Case Studies / Flame Sensor

Case Studies / Flame Sensor

Case Studies / Flame Sensor

Mobile Diagnostics Platform

Mobile Diagnostics Platform

Mobile Diagnostics Platform

Mobile‑first diagnostics built on LED parity, technician workflows, and real‑time IoT visibility

Mobile‑first diagnostics built on LED parity, technician workflows, and real‑time IoT visibility

Read time: 7–9 minutes

iPhone Focus → This case study emphasizes the iPhone experience, showcasing design system clarity and technician workflows, while Android delivery was achieved in parallel.

Chentronics, a leader in industrial flame detection, needed a mobile application to support technicians in the field. With the iScan®3+ launch approaching and competitors already offering mobile tools, the absence of a mobile diagnostic experience created operational risk, competitive pressure, and workflow friction

I designed and delivered a cross‑platform mobile system that gives technicians real‑time visibility into flame signals, LED states, and device health — directly on‑site, without relying on desktop tools.

Chentronics, a leader in industrial flame detection, needed a mobile application to support technicians in the field. With the iScan®3+ launch approaching and competitors already offering mobile tools, the absence of a mobile diagnostic experience created operational risk, competitive pressure, and workflow friction

I designed and delivered a cross‑platform mobile system that gives technicians real‑time visibility into flame signals, LED states, and device health — directly on‑site, without relying on desktop tools.

Client / Chentronics

Client / Chentronics

Client/ Chentronics

Category / IoT Connected Sensors

Category / IoT Connected Sensors

Category/ IoT Connected Sensors

Team / UX, Product, Engineering

Team / UX, Product, Engineering

Team / UX, Product, Engineering

Platform / Custom‑React Native (iOS/Android)

Platform / Custom‑React Native (iOS/Android)

Platform / Custom‑React Native (iOS/Android)

iPhone Focus → This case study emphasizes the iPhone experience, showcasing design system clarity and technician workflows, while Android delivery was achieved in parallel.

iPhone Focus → This case study emphasizes the iPhone experience, showcasing design system clarity and technician workflows, while Android delivery was achieved in parallel.

Outcome Summary

Technician Efficiency

Technician Efficiency

Technician Efficiency

• Faster commissioning and on‑site diagnostics

• Reduced support calls through clearer workflows

• Competitive parity with Forney’s HD Detector

• Scalable foundation for future hardware

• Faster diagnostics

• Real‑time visibility

• Reduced misinterpretation

• Field‑ready workflows

• Faster diagnostics

• Real‑time visibility

• Reduced misinterpretation

• Field‑ready workflows

Engineering Alignment

Engineering Alignment

Engineering Alignment

• LED parity between hardware and UI

• Predictable Bluetooth behavior and pairing logic

• Real‑time data modeling aligned with device firmware

• Cross‑platform consistency across React Native

• Predictable Bluetooth behavior and pairing logic

• LED parity between hardware and UI

• Real‑time data modeling aligned with device firmware

• Cross‑platform consistency across React Native

• LED parity

• Bluetooth behavior

• Real‑time data modeling

• Cross‑platform consistency (.NET MAUI)

Business Value

Business Value

Business Value

• Launching in 2026 in the Apple Store

• Expands Chentronics’ mobile footprint

• Competitive with major industrial sensor platforms

• Lowers support demand with on‑site diagnostics

• Launching in 2026 in the Apple Store

• Expands Chentronics’ mobile footprint

• Competitive with major industrial sensor platforms

• Lowers support demand with on‑site diagnostics

• Launching in 2026 in the Apple Store

• Expands Chentronics’ mobile footprint

• Competitive with major industrial sensor platforms

• Lowers support demand with on‑site diagnostics

Before → What wasn't working

Understanding the problem

Technicians relied on desktop‑bound tools for real‑time diagnostics. Without mobile access to flame signals, LED logic, or device health indicators, troubleshooting was slow, error‑prone, and increasingly out of step with an IoT‑driven market.

Technicians relied on desktop‑bound tools for real‑time diagnostics. Without mobile access to flame signals, LED logic, or device health indicators, troubleshooting was slow, error‑prone, and increasingly out of step with an IoT‑driven market.

What was found

• Diagnostics tied to static desktop tools

• Manual interpretation increased errors

• No mobile workflow for on‑site task

Why It mattered

• Technicians couldn’t troubleshoot in real time

• Increased downtime and delayed root‑cause analysis

• Higher error rates from manual interpretation

• More support escalations and field service costs

• Competitive risk as mobile solutions became industry standard

What It mattered

Technicians couldn’t troubleshoot in real time

Increased downtime and delayed root‑cause analysis

Higher error rates from manual interpretation

More support escalations and field service costs

Competitive risk as mobile solutions became industry standard

Impact (After)

A shared baseline of workflow pain points that guided engineering, clarified priorities, and established the need for a mobile‑first diagnostic model.

Before → Competitive Analysis

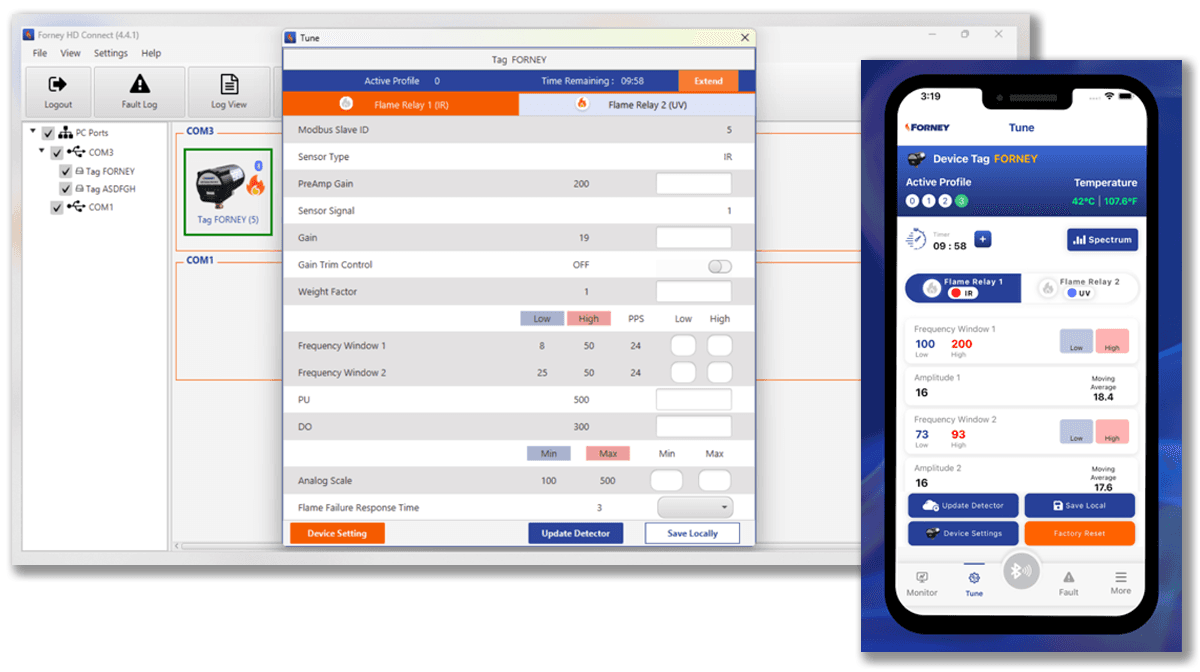

To benchmark technician workflows and interface clarity, Forney’s HD Detector app was analyzed and its visual patterns, color usage, and diagnostic logic was compared against Chentronics’ capabilities.

To benchmark technician workflows and interface clarity, Forney’s HD Detector app was analyzed and its visual patterns, color usage, and diagnostic logic was compared against Chentronics’ capabilities.

What was found

• Orange used as a primary color, risking confusion

• No clear hierarchy for status indicators

• Low and high states shown in identical green

• LED logic not reflected in app visuals

What was found

• Orange used as a primary color, risking confusion

• No clear hierarchy for status indicators

• Low and high states shown in identical green

• LED logic not reflected in app visuals

Why it mattered

Orange typically signals warnings in technician workflows

Lack of color hierarchy reduced scan clarity

LED status was a competitive differentiator

Chentronics hardware offered stronger visual feedback

What It mattered

Orange typically signals warnings in technician workflows

Lack of color hierarchy reduced scan clarity

LED status was a competitive differentiator

Chentronics hardware offered stronger visual feedback

Impact (After)

Identified critical usability gaps and surfaced LED logic as a competitive advantage shaping the mobile UI strategy around real‑time status clarity and accessible color hierarchy.

Before → Workflow Analysis

Technician workflows were built for desktop environments, not mobile responsiveness. Field users lacked clear interaction models for diagnostics, pairing, and status interpretation.

Technician workflows were built for desktop environments, not mobile responsiveness. Field users lacked clear interaction models for diagnostics, pairing, and status interpretation.

What was found

• No mobile logic for pairing or diagnostics

• Steps buried in static desktop menus

• Status feedback delayed or unclear

• Field conditions not reflected in UI behavior

What was found

• No mobile logic for pairing or diagnostics

• Steps buried in static desktop menus

• Status feedback delayed or unclear

• Field conditions not reflected in UI behavior

What was done

• Mapped technician tasks across desktop workflows

• Identified decision points and diagnostic bottlenecks

• Flagged friction in password loops and scan selection

• Reframed steps into mobile‑first interaction models

What was done

• Mapped technician tasks across desktop workflows

• Identified decision points and diagnostic bottlenecks

• Flagged friction in password loops and scan selection

• Reframed steps into mobile‑first interaction models

Why it mattered

• Field users needed fast, intuitive workflows

• Mobile UI had to mirror real‑world technician behavior

• Reducing steps improved clarity and task completion

• Workflow logic became the foundation for mobile design

Why it mattered

• Field users needed fast, intuitive workflows

• Mobile UI had to mirror real‑world technician behavior

• Reducing steps improved clarity and task completion

• Workflow logic became the foundation for mobile design

Impact (After)

Established mobile workflows that mirrored technician tasks, reduced cognitive load, and improved diagnostic speed.

Impact (After)

Established mobile workflows that mirrored technician tasks, reduced cognitive load, and improved diagnostic speed.

Impact (After)

Established mobile workflows that mirrored technician tasks, reduced cognitive load, and improved diagnostic speed.

During → Data Visualization

Real‑Time Flame Signals, LED States, and Spectrum Analysis

Technicians needed a mobile‑friendly way to interpret flame signals, LED states, and frequency spectrum data. Desktop tools were too dense and lacked real‑time clarity.

Real‑Time Flame Signals, LED States, and Spectrum Analysis

Technicians needed a mobile‑friendly way to interpret flame signals, LED states, and frequency spectrum data. Desktop tools were dense, slow, and hard to scan in field conditions.

Real‑Time Flame Signals, LED States, and Spectrum Analysis

Technicians needed a mobile‑friendly way to interpret flame signals, LED states, and frequency spectrum data. Desktop tools were dense, slow, and hard to scan in field conditions.

What was found

No mobile representation of LED behavior

Flame signal data difficult to interpret on small screens

Spectrum analysis buried in desktop tools

Field users needed fast, glanceable status cues

What was found

No mobile representation of LED behavior

Flame signal data hard to interpret on small screens

Spectrum analysis buried in desktop tools

Field users needed fast, glanceable status cues

What was found

No mobile representation of LED behavior

Flame signal data difficult to interpret on small screens

Spectrum analysis buried in desktop tools

Field users needed fast, glanceable status cues

What was designed

On‑screen LED indicators mirroring hardware behavior

A mobile‑optimized flame frequency spectrum chart

Clear iconography and color coding for rapid scanning

Layouts structured for field visibility and low‑light condition

What was designed

• On‑screen LED indicators mirroring hardware behavior

• Mobile‑optimized flame frequency spectrum chart

• Iconography for signal status, gain, and temperature thresholds

• Semantic color for temperature, alerts, and diagnostic states

• Layouts structured for field visibility and low‑light condition

What was designed

On‑screen LED indicators mirroring hardware behavior

A mobile‑optimized flame frequency spectrum chart

Clear iconography and color coding for rapid scanning

Layouts structured for field visibility and low‑light condition

Why it mattered

Technicians rely on LED logic for real‑time decisions

Visual parity reduced misreads in the field

Clear iconography accelerated diagnostics

Semantic color improved scan clarity and reduced support calls

Real‑time visuals built trust between hardware and UI

Why it mattered

Technicians rely on LED logic for real‑time decisions

Visual parity reduced misinterpretation in the field

Mobile charts accelerated diagnostics

Clear visuals improved confidence and reduced support calls

Why it mattered

• Technicians rely on LED logic for real‑time decisions

• Visual parity reduced misreads in the field

• Clear iconography accelerated diagnostics

• Semantic color improved scan clarity and reduced support calls

• Real‑time visuals built trust between hardware and UI

Impact (After)

Delivered mobile‑ready visualizations that mirrored hardware behavior and enabled instant interpretation in real‑world conditions.

Impact (After)

Delivered mobile‑ready visualizations that mirrored hardware behavior and enabled instant interpretation in real‑world conditions.

Impact (After)

Delivered mobile‑ready visualizations that mirrored hardware behavior and enabled instant interpretation in real‑world conditions.

During → Pivoting the System: Accessible, Field‑Ready Color Model

The existing brand palette wasn’t designed for digital products or field conditions. Orange dominated the identity, but its saturation typically signals warnings in technician workflows.

What Was Found

No hierarchy for status or diagnostic states

Orange overused as a primary UI color

Limited palette for low‑light environments

Brand colors not optimized for mobile screens

What was found

No hierarchy for status or diagnostic states

Orange overused as a primary UI color

Limited palette for low‑light environments

Brand colors not optimized for mobile screens

What Was Designed

• Expanded palette for clear, usable UI

• Added status colors for alerts and gain

• Tinted orange for non‑warning use

• Defined colors for charts, LEDs, plots

• Built for low‑light, field usability

What was designed

• Expanded palette for clear, usable UI

• Added status colors for alerts and gain

• Tinted orange for non‑warning use

• Defined colors for charts, LEDs, plots

• Built for low‑light, field usability

Why It Mattered

Technicians rely on color for fast interpretation

Clear hierarchy reduces misreads in high‑pressure environments

Accessible colors improve visibility in low‑light conditions

Why it mattered

Technicians rely on color for fast interpretation

Clear hierarchy reduces misreads in high‑pressure environments

Accessible colors improve visibility in low‑light conditions

Impact (After)

A scalable, accessible color system that reinforced brand identity while supporting real‑time diagnostics.

Impact (After)

A scalable, accessible color system that reinforced brand identity while supporting real‑time diagnostics.

Impact (After)

A scalable, accessible color system that reinforced brand identity while supporting real‑time diagnostics.

During → Unified Layout Strategy

Before high‑fidelity design, early wireframes visualized interaction logic, surfaced edge cases, and aligned the remote engineering team around mobile behavior.

Before high‑fidelity design, early wireframes visualized interaction logic, surfaced edge cases, and aligned the remote engineering team around mobile behavior.

Before high‑fidelity design, early wireframes visualized interaction logic, surfaced edge cases, and aligned the remote engineering team around mobile behavior.

What was found

Diagnostic steps needed restructuring

Desktop logic didn’t translate cleanly to mobile

Alerts and states required clearer hierarchy

Team needed visual clarity to validate assumptions

What was found

Diagnostic steps needed restructuring

Desktop logic didn’t translate cleanly to mobile

Alerts and states required clearer hierarchy

Team needed visual clarity to validate assumptions

What was designed

• Low‑fidelity sketches mapping technician tasks

• Annotated flows showing alerts, states, and transitions

• Mobile‑first layouts emphasizing scan clarity

• Early concepts for pairing, monitoring, and diagnostics

What We Designed

• Low‑fidelity sketches mapping technician tasks

• Annotated flows showing alerts, states, and transitions

• Mobile‑first layouts emphasizing scan clarity

• Early concepts for pairing, monitoring, and diagnostics

Why it mattered

• Wireframes reduced ambiguity early

• Provided a shared reference for engineering

• Exposed workflow gaps before high‑fidelity work

• Accelerated alignment across a remote team

Why it mattered

• Wireframes reduced ambiguity early

• Provided a shared reference for engineering

• Exposed workflow gaps before high‑fidelity work

• Accelerated alignment across a remote team

Impact (After)

A validated foundation for mobile workflows that mirrored real technician behavior and reduced cognitive load.

Impact (After)

A validated foundation for mobile workflows that mirrored real technician behavior and reduced cognitive load.

Impact (After)

A validated foundation for mobile workflows that mirrored real technician behavior and reduced cognitive load.

During → Building Trust with a Remote, UX‑New Engineering Team

The engineering team had never collaborated with a UX designer, creating uncertainty around feedback, version control, and design intent.

The engineering team had never collaborated with a UX designer, creating uncertainty around feedback, version control, and design intent.

The engineering team had never collaborated with a UX designer, creating uncertainty around feedback, version control, and design intent.

What was found

Feedback scattered across channels

No existing UX review process

Limited visibility into design status

Team unsure how to evaluate UI decisions

What was designed

Used Figma comments for contextual, element‑level feedback

Organized pages to show status, versions, and evolution

Guided the team on how to review and respond effectively

What was found

Feedback scattered across channels

No existing UX review process

Limited visibility into design status

Team unsure how to evaluate UI decisions

What was designed

Used Figma comments for contextual, element‑level feedback

Organized pages to show status, versions, and evolution

Guided the team on how to review and respond effectively

Why it mattered

Reduced rework by aligning early and often

Improved clarity across a distributed team

Built confidence in structured design governance

Enabled faster iteration with fewer misunderstandings

Why it mattered

Reduced rework by aligning early and often

Improved clarity across a distributed team

Built confidence in structured design governance

Enabled faster iteration with fewer misunderstandings

Impact (After)

Enabled effective collaboration through clear feedback systems, transparent versioning, and predictable review cycles.

Impact (After)

Enabled effective collaboration through clear feedback systems, transparent versioning, and predictable review cycles.

Impact (After)

Enabled effective collaboration through clear feedback systems, transparent versioning, and predictable review cycles.

Technicians needed a clear way to evaluate flame sensor behavior before development. Static documentation and desktop tools made it difficult to visualize real‑time interactions, slowing alignment across engineering, product, and field teams.

What Was Found

• Hard to visualize LED logic from documentation

• No way to simulate device states or settings

• Stakeholders struggled to interpret diagnostic flows

• Requirements unclear without interactive context

What Was Designed

Clickable prototypes simulating connected devices

Interactive flows for pairing, monitoring, and diagnostics

LED state simulations mirroring hardware behavior

Mobile‑first layouts for real‑time evaluation

Why It Mattered

Enabled early validation of diagnostic workflows

Reduced ambiguity around device behavior

Improved stakeholder confidence in the subscription model

Surfaced edge cases before engineering investment

Outcome → Delivered interactive prototypes that aligned stakeholders early, clarified requirements, and accelerated the path to development by visualizing real‑time sensor interactions in a mobile context.

DURING → Simulating Device Behavior Before Development

Technicians needed a clear way to evaluate flame sensor behavior before development. Static documentation and desktop tools made it difficult to visualize real‑time interactions, slowing alignment across engineering, product, and field teams.

What it mattered

Enabled early validation of diagnostic workflows

Reduced ambiguity around device behavior

Improved stakeholder confidence in the subscription model

Surfaced edge cases before engineering investment

What was designed

Clickable prototypes simulating connected devices

Interactive flows for pairing, monitoring, and diagnostics

LED state simulations mirroring hardware behavior

Mobile‑first layouts for real‑time evaluation

What was found

Hard to visualize LED logic from documentation

No way to simulate device states or settings

Stakeholders struggled to interpret diagnostic flows

Requirements unclear without interactive context

Outcome →Delivered interactive prototypes that aligned stakeholders early, clarified requirements, and accelerated the path to development by visualizing real‑time sensor interactions in a mobile context.

DURING → Simulating Device Behavior Before Development

During → Simulating Device Behavior Before Development

Technicians needed a clear way to evaluate flame sensor behavior before development. Static documentation made it difficult to visualize real‑time interactions.

What was found

• Hard to visualize LED logic from documentation

• No way to simulate device states or settings

• Stakeholders struggled to interpret diagnostic flows

• Requirements unclear without interactive context

What was designed

Clickable prototypes simulating connected devices

Interactive flows for pairing, monitoring, and diagnostics

LED state simulations mirroring hardware behavior

Mobile‑first layouts for real‑time evaluation

Why it mattered

Enabled early validation of diagnostic workflows

Reduced ambiguity around device behavior

Improved stakeholder confidence in the subscription model

Surfaced edge cases before engineering investment

Impact (After)

Delivered interactive prototypes that aligned stakeholders early and accelerated development by visualizing real‑time sensor interactions.

After → Final Screens & Impact

These screens represent the iScan3+ mobile experience across core technician workflows. The final UI brings real‑time diagnostics, LED parity, and field‑ready interaction models into a single, mobile‑first system that mirrors how technicians work on‑site.

These screens represent the iScan3+ mobile experience across core technician workflows. The final UI brings real‑time diagnostics, LED parity, and field‑ready interaction models into a single, mobile‑first system that mirrors how technicians work on‑site.

These screens represent the iScan3+ mobile experience across core technician workflows. The final UI brings real‑time diagnostics, LED parity, and field‑ready interaction models into a single, mobile‑first system that mirrors how technicians work on‑site.

What the screens demonstrate

Real‑time device pairing and status visibility

LED logic mirrored directly from hardware

Mobile‑optimized flame signal and spectrum charts

Clear hierarchy for alerts, gain, and diagnostic states

Plant‑level organization for multi‑device environments

Outcome What The Screens Demonstrate

LED logic mirrored directly from hardware

Real‑time device pairing and status visibility

Mobile‑optimized flame signal and spectrum charts

Clear hierarchy for alerts, gain, and diagnostic states

Plant‑level organization for multi‑device environments

Why it mattered

Diagnostic steps are faster and easier to interpret

Technicians get instant clarity in the field

Color and iconography reduce misreads under pressure

Mobile workflows align with real‑world technician behavior

Cross‑platform consistency supports a single codebase

Why it Mattered

Diagnostic steps are faster and easier to interpret

Technicians get instant clarity in the field

Color and iconography reduce misreads under pressure

Mobile workflows align with real‑world technician behavior

Cross‑platform consistency supports a single codebase

Impact (After)

A cohesive, technician‑centered mobile experience that supports real‑time diagnostics, reduces cognitive load, and strengthens Chentronics’ competitive position with a modern, IoT‑ready application for both iPhone and Android.

Impact (After)

A cohesive, technician‑centered mobile experience that supports real‑time diagnostics, reduces cognitive load, and strengthens Chentronics’ competitive position with a modern, IoT‑ready application for both iPhone and Android.

Impact (After)

A cohesive, technician‑centered mobile experience that supports real‑time diagnostics, reduces cognitive load, and strengthens Chentronics’ competitive position with a modern, IoT‑ready application for both iPhone and Android.

Note → The app is available for both Android and iPhone.

Note → The app is available for both Android and iPhone.

Note → The app is available for both Android and iPhone.

Other Projects

Paul Wentzell

Enterprise Product Designer

Paul Wentzell

Enterprise Product Designer

AI Assistant

Virtual Paul